Préparation pour la documentation technique

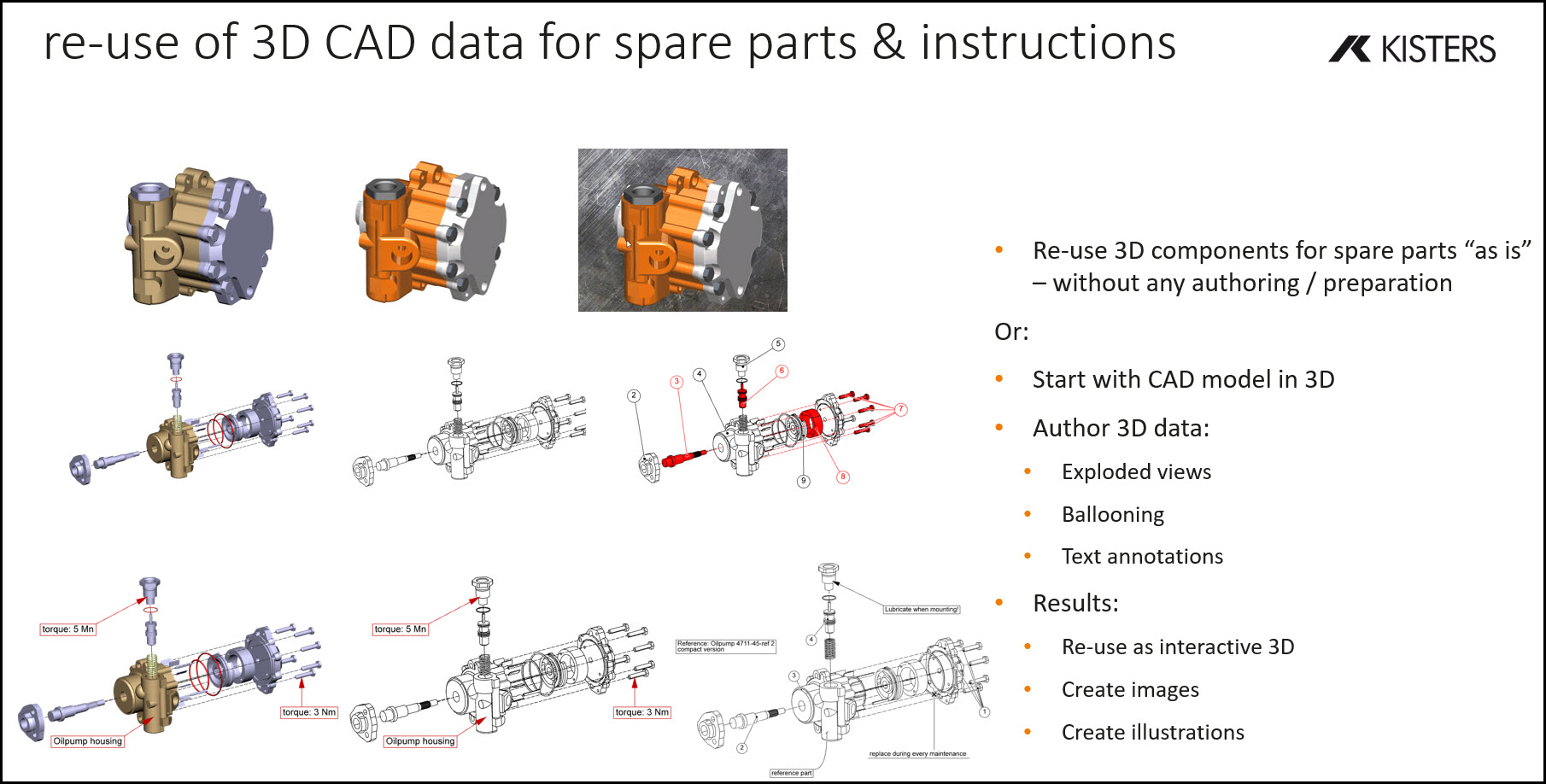

Réutiliser les modèles CAO 3D : pour la fabrication, la maintenance / le service après-vente, les pièces de rechange

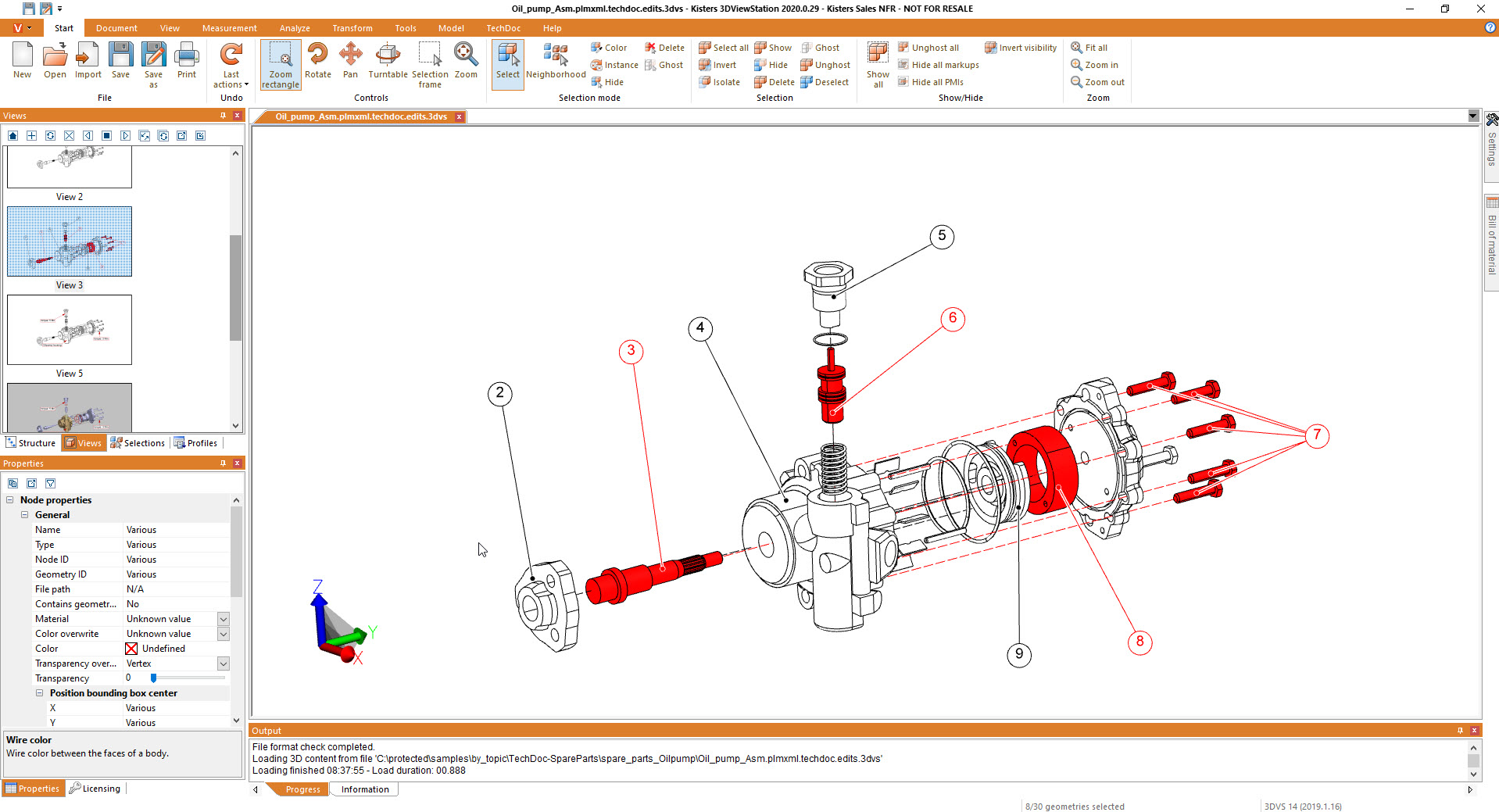

- La 3DViewStation lit les données CAO 3D provenant de différentes sources, telles que Catia, NX, Creo, Inventor, Solidworks, Solidedge, JT, PDF 3D...

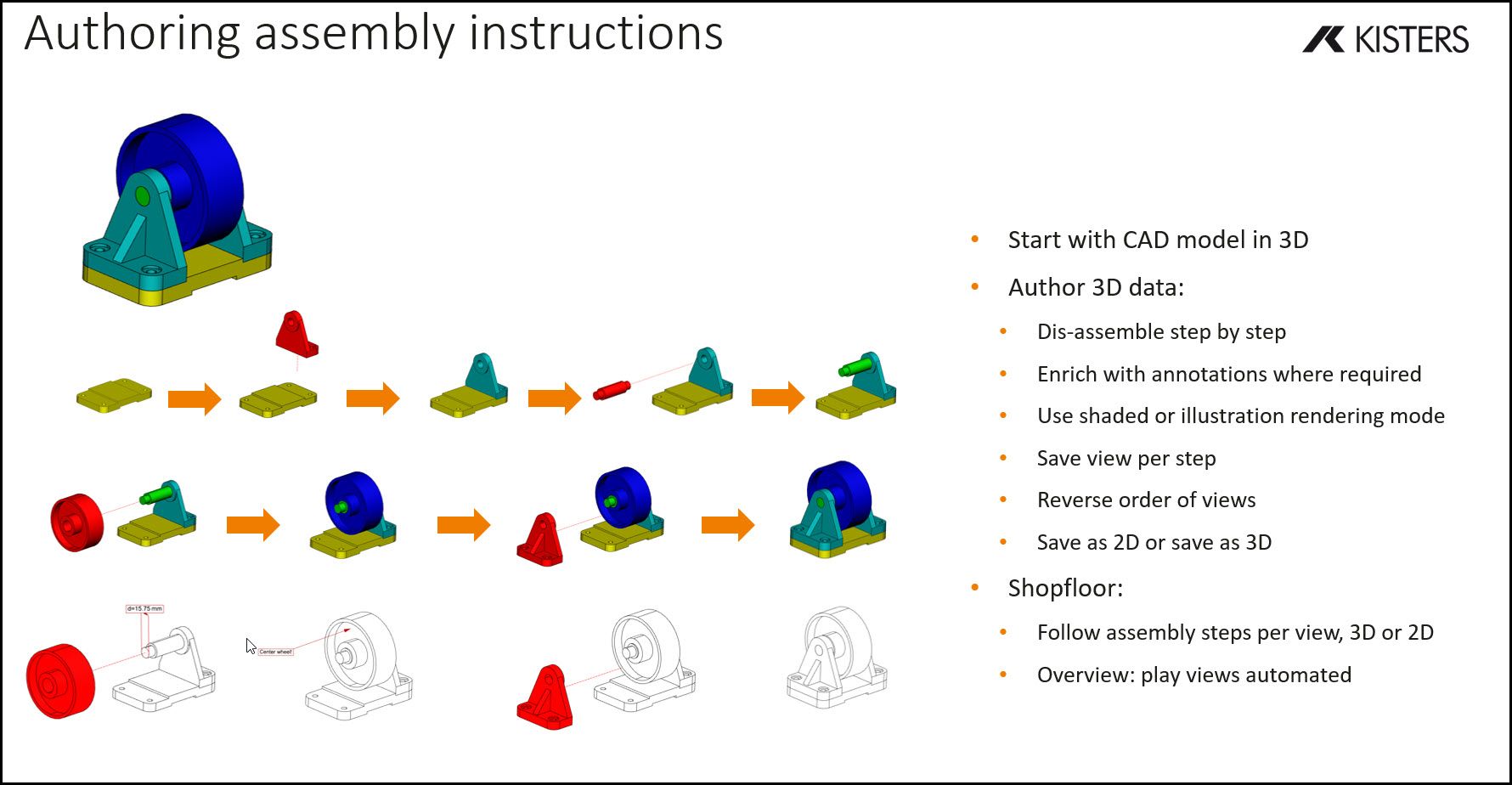

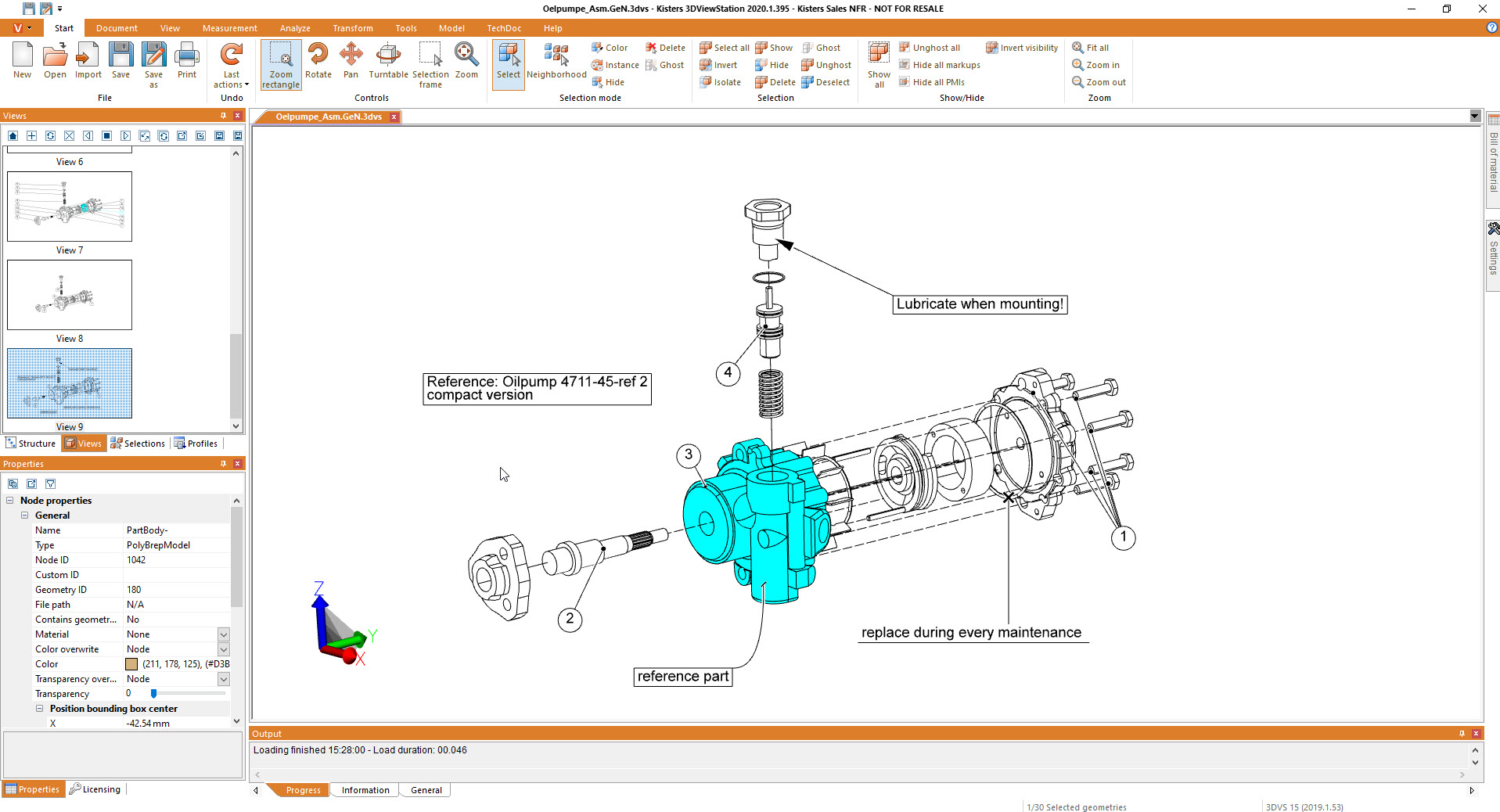

- Il permet de manipuler des données CAO 3D complexes, telles que l'affichage/le masquage d'objets, la modification de la couleur et de la transparence, le déplacement et la rotation d'objets, la mise en miroir d'objets, l'explosion d'assemblages, la création de lignes de décalage, etc

- Ajout d'annotations, ajout de textes fixes, importation de géométries/symboles 3D auxiliaires

- La 3DViewStation propose différentes options pour les styles de cadre, les styles de ligne, les types de fin, les couleurs, les polices, etc

- Création d'une nomenclature (BOM, Bill of Material) à partir de l'assemblage chargé

- Il reconnaît les identifiants de connexion générés manuellement ou automatiquement

- Génération manuelle ou automatique de callouts

- Positionnement ou réorganisation des légendes manuellement ou automatiquement (en haut, en bas, le plus proche...), même pendant la rotation d'un modèle

- La 3DViewStation peut organiser le contenu sous forme de vues

- Lire les vues animées

- Exporter des vues vers un fichier 2D ou les copier dans le presse-papiers

- Exporter en 3D

- La 3DViewStation peut être utilisée à la fois comme outil de création et pour afficher les résultats

- Possibilité de combiner les produits : par exemple, utiliser la version de bureau comme outil d'auteur, utiliser la version WebViewer pour afficher les résultats, ou vice versa

- La 3DViewStation peut être utilisée sur des PC de bureau, des ordinateurs portables de bureau, des tablettes, des smartphones et dans des environnements VR

- La 3DViewStation peut être utilisée de manière autonome ou intégrée avec les applications MRO / SLM / After Sales / Service / Pièces de rechange

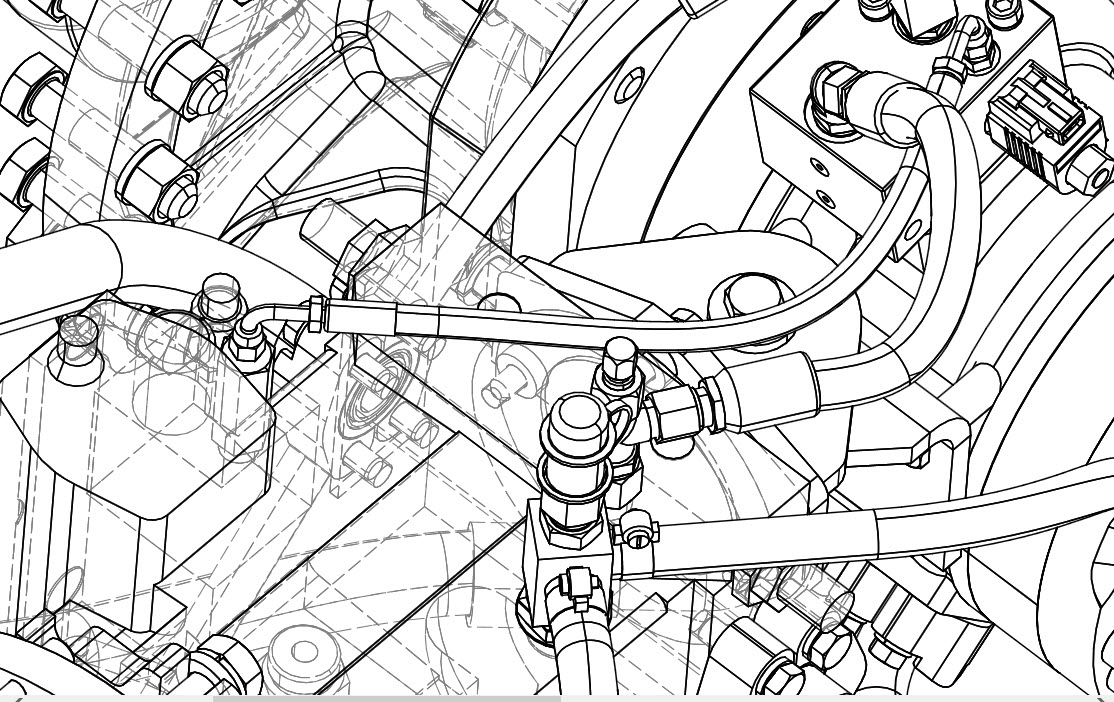

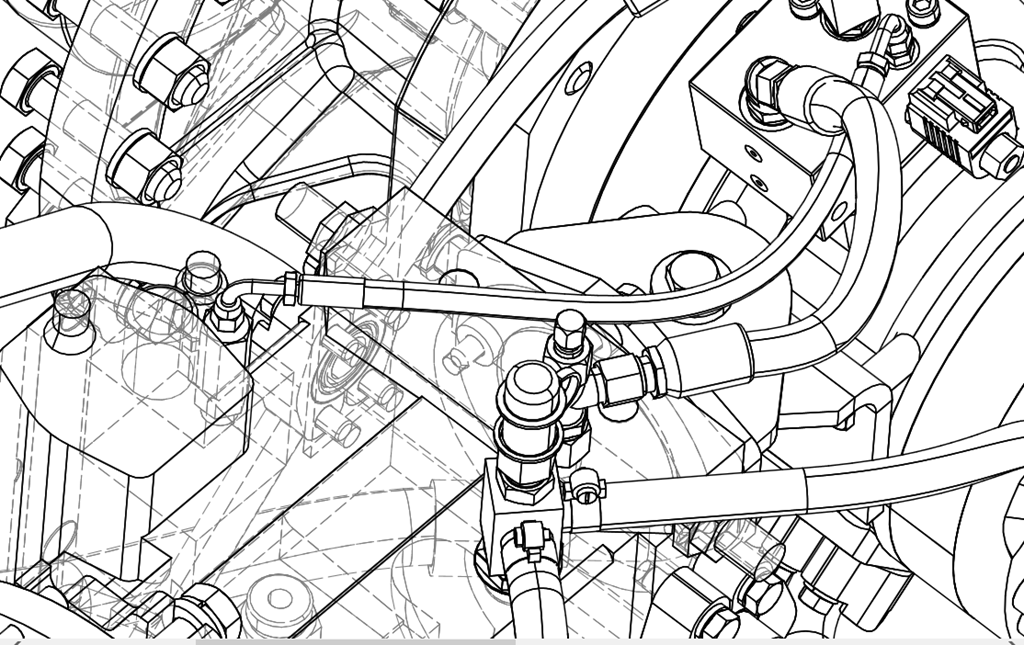

When talking about 2D exports, first of all we should mention, that it is no trivial task to derive a full scale, high quality, still small 2D vector representation for a 3D CAD model. At the same time generating an image, like a thumbnail preview of even a high resolution image is rather easy.

What do I need to know when exporting from a 3D-CAD model to a 2D vector file?

Determining the appropriate file format for the vector file is key. In the manufacturing industry common file formats used for 2D drawings include 2D DXF (Drawing Exchange Format), 2D PDF (Portable Document Format) and SVG (Scalable Vector Graphics). Sometimes the file format required depends on the target application and system, where it will be used.

Organize your CAD model into appropriate layers and/or blocks before exporting. This allows for better control over different components, annotations, or visual elements in the vector file. 3DViewStation APIs and our batch tool KAS allow to automatically build layers and blocks, based on the product structure of the 3D-CAD model.

Familiarize yourself with the export settings and APIs provided by 3DViewStation and KAS. These settings may include options for curve smoothing, resolution, and compatibility with different software or devices. Decide whether you want to include hidden lines in the exported vector file or show only visible lines. Depending on the purpose of the 2D representation, you may need to enable or disable hidden line removal to accurately represent the design.

3DViewStation and KAS can help you simplifying or optimizing the geometry of your 3D CAD model before exporting to a 2D vector file. They allow to remove unnecessary details, such as internal components or hidden features, to keep the resulting vector file clean and lightweight. This can help improve performance and reduce file size.

Consider the desired level of quality and precision in the exported vector file. This relates to the smoothness of curves, accuracy of angles, and overall detail. Higher quality settings may result in larger file sizes, so balance your requirements with file size considerations. Very often it is crucial to keep file size as small as possible, which requires intelligent vectorization and compression algorithms, like 3DViewStation and KAS provide.

We need to ensure that the dimensions of your 3D model are accurately translated to the 2D vector file. Check the scaling and units of measurement to avoid any discrepancies. File formats like PDF know their paper size, which might make it easier to retain the intended scale during the conversion.

Leveraging 3DViewStation Desktop or WebViewer version you can verify that the exported vector file represents the desired geometry and level of detail. Pay attention to curves, arcs, and splines, as they may require higher resolution or special settings to maintain smoothness.

Some file formats do support line thickness and styles. As 3D CAD model do not have any settings like that, we’ll need to specify them in such a case. Different software may handle linework differently, so be prepared to adjust these settings during the export process.

3DViewStation and KAS will care for colors and fills automatically, depending on black & white or color setting: You can assign specific colors to different layers or components, interactively or via API or opt for a monochromatic representation during export.

Finally, if your 3D CAD model includes 3D annotations, labels, dimensions, balloons, tables or text blocks, verify that they are appropriately exported and legible in the 2D vector file. These annotations are essential for conveying important information about the design and can aid in manufacturing or construction processes.