Visualization for Product Configurators

Use the 3DViewStation to leverage powerful 3D visualization for your product configurator

You operate a configurator on the web or you are the manufacturer of a CPQ (Cost/Price/Quote) solution. Your solution knows everything about the product to be configured - it knows the configuration rules as well as the prices of the components, has access to the corresponding geometries, but, is a powerful visualization aspect is missing? The Kisters 3DViewStation WebViewer version is the perfect addition to your solution. If you’d like to to configure your products within a PLM system or simply visualize the possible, predefined product variants (which are often available as a matrix), the 3DViewStation as desktop, WebViewer version or even as VR edition is an option for you. Final results can be a 100% BOM, a 3D model and/or a 2D drawing. On the one hand, customers can use this software to see very quickly what the products will look like, making it easier for them to get in touch with the manufacturer. On the other hand, companies support their sales department, which can create tailor-made offers much more easily.

Advantages...

... for users

- Fast visual impression even with extremely complex products

- High quality display thanks to material support

- Simple operation

... for developers

- Allows you to implement all possible approaches to product configuration - not limited to 150% models

- Rapid implementation of an integration

- Few lines of programming code required, as no SDK

- Only minor adjustments necessary when switching between desktop, web/mobile and VR integrations

- Competent consulting team helps with all integration questions

... for decision makers

- Exact 100% BOM as basis for the Digital Twin

- Many security features protect your know-how

- Differently equipped clients for end customers and internal users possible

- Only one solution for 3D and 2D final results

- Many automation possibilities

- No training necessary

- No client installation necessary (with WebViewer)

Some advantages in the context of product configuration:

- More convincing appearance, faster contact to customers, more quotations, easier offer creation, increased sales.

- The visualization is extremely fast, shows configuration changes within a second, and runs in the cloud or on its own infrastructure.

- Geometries are loaded, positioned and scaled in real time. So avoid using a 150% model

- Still, it is also possible to use 150% models, which are reduced to 100% at runtime via a selection matrix.

- We support the use of beautiful materials and environmental images (2D or 360 degree images, 3D skyboxes) in real time.

- The 3DViewStation WebViewer can display complete products, which can even consist of 100,000 parts, in seconds - in the browser.

- The 3DViewStation Desktop version is often used for fat clients or as authoring system for the preparation of CAD data.

- You will be able to offer 2D drawing derivations that are automatically generated from the configured 3D model.

- The 3DViewStation helps you to protect your IP (Intellectual Property):

- When rendering in the browser, we do not transfer any 3D objects from the server to the client. It would be far too easy to tap into the 3D data.

- The 3DViewStation can prevent a user from cutting through certain parts or even the entire 3D model.

- You are able to automatically remove internal parts.

- In case you need to pass on BREP data to an outside participant: the 3DViewStation can change geometries in such a way that the change is hardly visible and the results will prove useless for production (this prevents illegal copies/plagiarism).

We would be happy to advise you

Sales Germany

+49 2408 9385 517

Sales USA

+1 916 723 1441

Some project details:

Today, the 3DViewStation is already used by companies to visualize configurable truck engines, complete trucks, complete helicopters, industrial air conditioning, electrical components and more. Integrated in special configurator software, but also PLM or ERP systems, used by a GmbH up to a large corporation.

The problem:

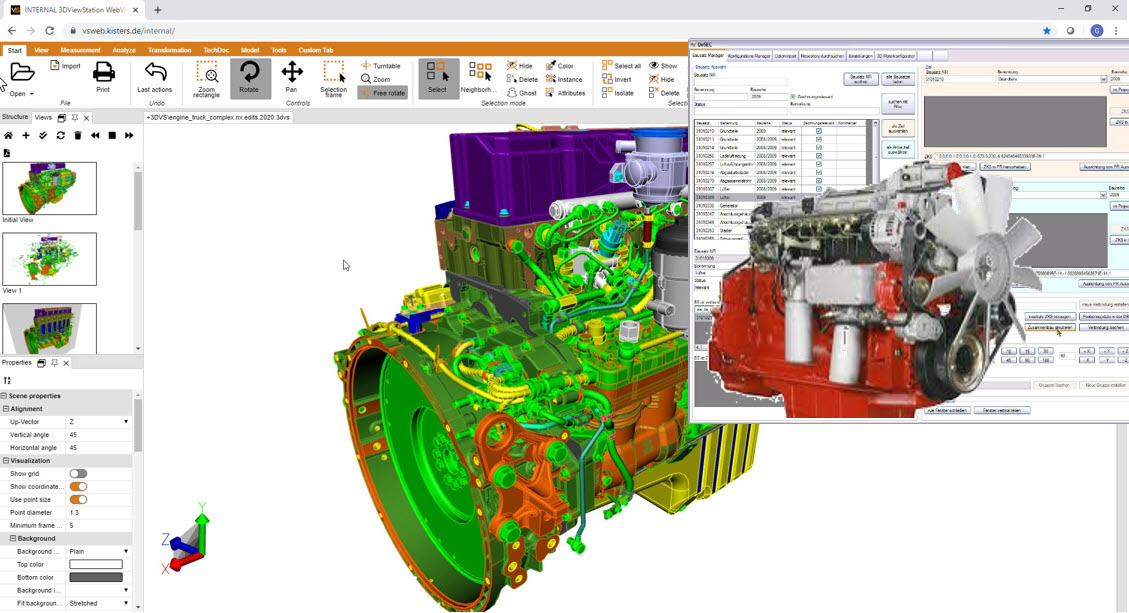

Deutz manufactures truck engines with an extremely high number of variants. Millions of different engines could be manufactured from over 15,000 components. All possible variants cannot be completely defined in advance using traditional CAD methods. The other problem was that the CAD system NX was not able to load a fully configured engine. Also, no neutral (STEP) models of the motors ordered could be made available to the enterprise. Therefore, another solution had to be found with which the sales department could convince customers, create offers and find the right price.

The solution:

The components are prepared once so that they "find their own position" on the engine. In the configuration process, only all subassemblies to be used have to be recorded. As soon as they are loaded in the viewer, an intelligent algorithm ensures that they are positioned correctly. Without this ever having happened in the CAD system. At Deutz, various 3DViewStation product variants are used in combination: the desktop version for preparation, our KAS batch tool for automation, and our 3DViewStation WebViewer version for runtime on the web.

The benefits:

During the configuration process, the customer can immediately see the future engine and make changes if necessary. The viewer is also extremely fast with complete engines, which are displayed down to the last screw, which is what Deutz impresses its customers with. After placing the order, the customer is provided with STEP files that have been reduced in such a way that the relevant geometries are true to the original, while others may have been removed or simplified. With the introduction of the configurator, Deutz has significantly reduced the effort involved in preparing an offer, simplified the calculation of prices and optimized sales. As a side effect, there are full bills of materials right from the start, which is important for manufacturing. The configuration result is also the basis for spare parts management, where the 3DViewStation is also used as a CAD viewer.

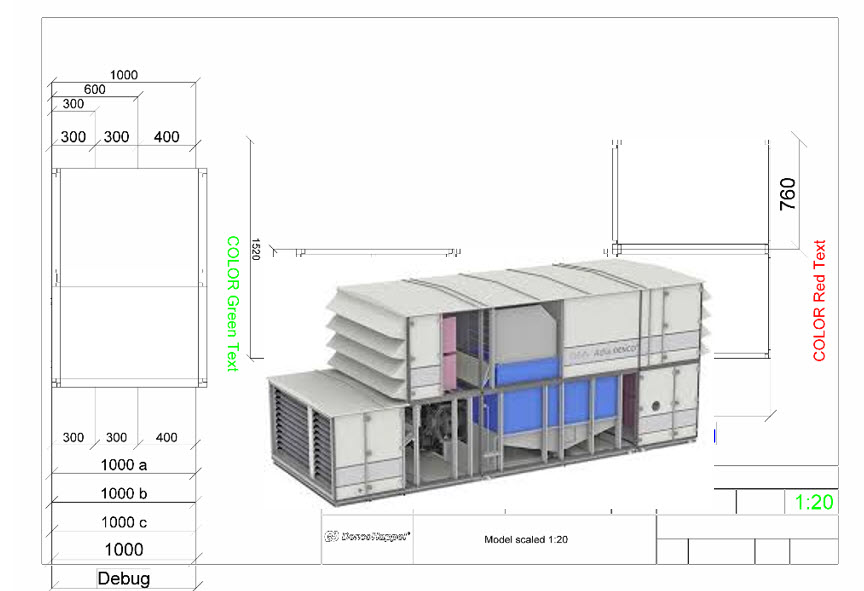

The problem:

Fläkt manufactures industrial air conditioning systems, which consist of different components depending on the task. These components must be assembled together at specific positions in the context of a building. Legally binding, high-quality 2D drawings for the offer documentation must then be derived from this customer-specific configured assembly, to which a preview image and a 3D model are added.

Fläkt had already invested a lot of money in trying alternative solutions before they approached us.

The solution:

At that time, the 3DViewStation had everything in the 3D area that Fläkt needed: various CAD interfaces for importing 3D CAD data from a wide variety of CAD systems, fast graphics, the necessary APIs (programming interface) for loading and correct positioning of the components, a dimensioning function in the 3D As part of the project, the rudimentary function for exporting 2D drawings based on a 3D model was significantly expanded and made faster. Since the configurator application itself is web-based, the 3DViewStation WebViewer version is used here.

The Benefits:

Due to many automatisms and very little manual work, the creation of the complete offer documentation for Fläkt has now become a faster and safer process. Since then, several thousand sales employees who use the configurator every day have been selling the air conditioning systems much more successfully than before.

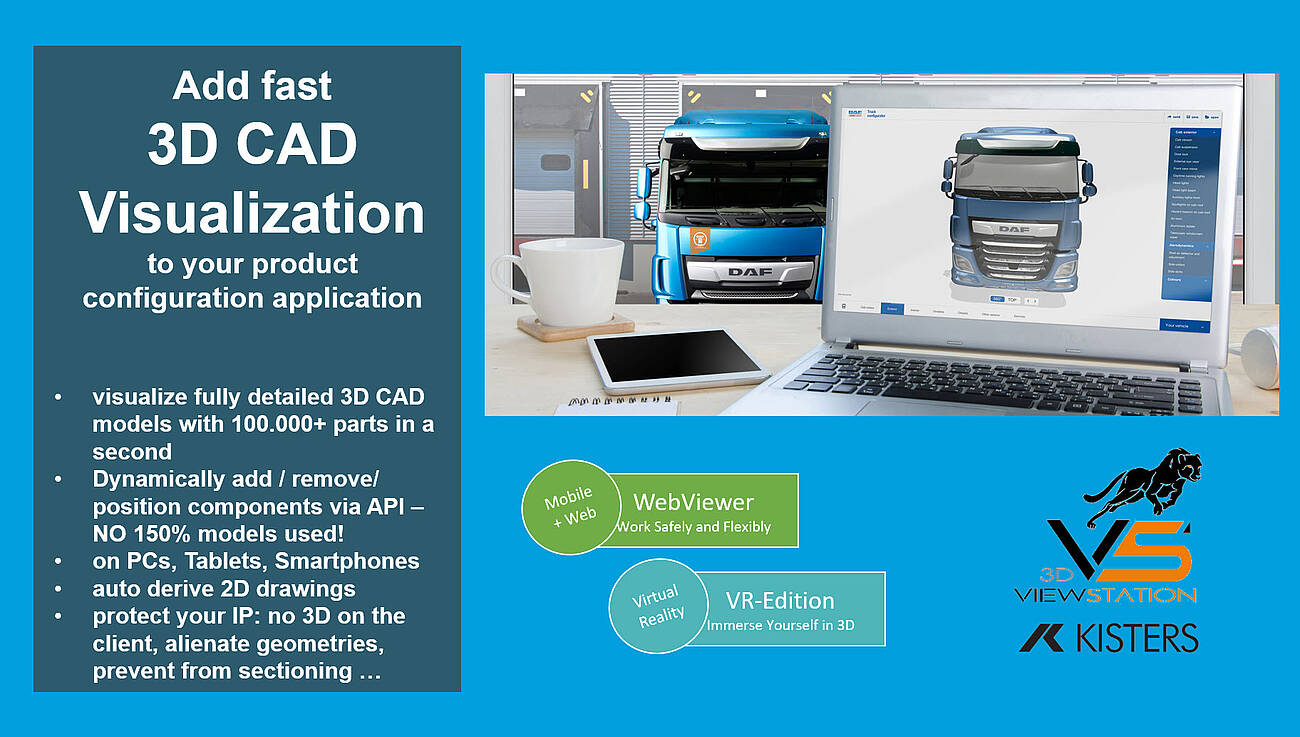

The problem:

DAF (member of Paccar group) was looking for a solution to modernize the truck configurator so that the previous 2D images of a generic truck are replaced by attractive, interactive, real-time rendered 3D models of the actual configured truck. The manufacturers of the CAD systems were first looked for, but no solution was found.

In addition to the 3D visualization, STEP and JT data should also be exportable. However, since there are many customers who still work with 2D CAD, the previous generic 2D drawings had to be replaced by exact 2D drawings derived from the 3D model of the configured truck.

The solution:

Today, the Kisters 3DViewStation WebViewer version is used for the graphics. The decisive factor was that it was the only solution available on the market that could prove that a complete truck, including all individual parts, could be visualized very quickly in the cloud. The 3DViewStation already had an export to STEP and JT. As part of the project, the "beautiful" rendering was implemented using materials, background images and skyboxes. The 2D drawing output has also been heavily revised, with multiple views, layers and blocks. The know-how protection model was implemented as the last extension for the time being, with which invisible objects can be removed and geometries can be alienated in a targeted manner. Today the solution runs in the Azure Cloud, where no native 3D CAD data from NX or Creo is loaded, only pre-converted 3DVS data that can contain both tessellation and BREP.

The Benefits:

DAF is now selling more trucks than ever and has been able to measure the success of the new configurator well. All customers enjoy the real-time and beautifully rendered trucks. The producers of the bodies (“rigid” truck variant) in particular are very satisfied that they can now not only see the actual truck. With their own access, they can now access all the required dimensions in the 3D model or, alternatively, access high-quality 2D drawings that match the configured truck.

The know-how protection (IPP) module ensures that fewer plagiarisms are produced and DAF sells more original spare parts. Finally, we won the Digital Innovation of the Year award with DAF.

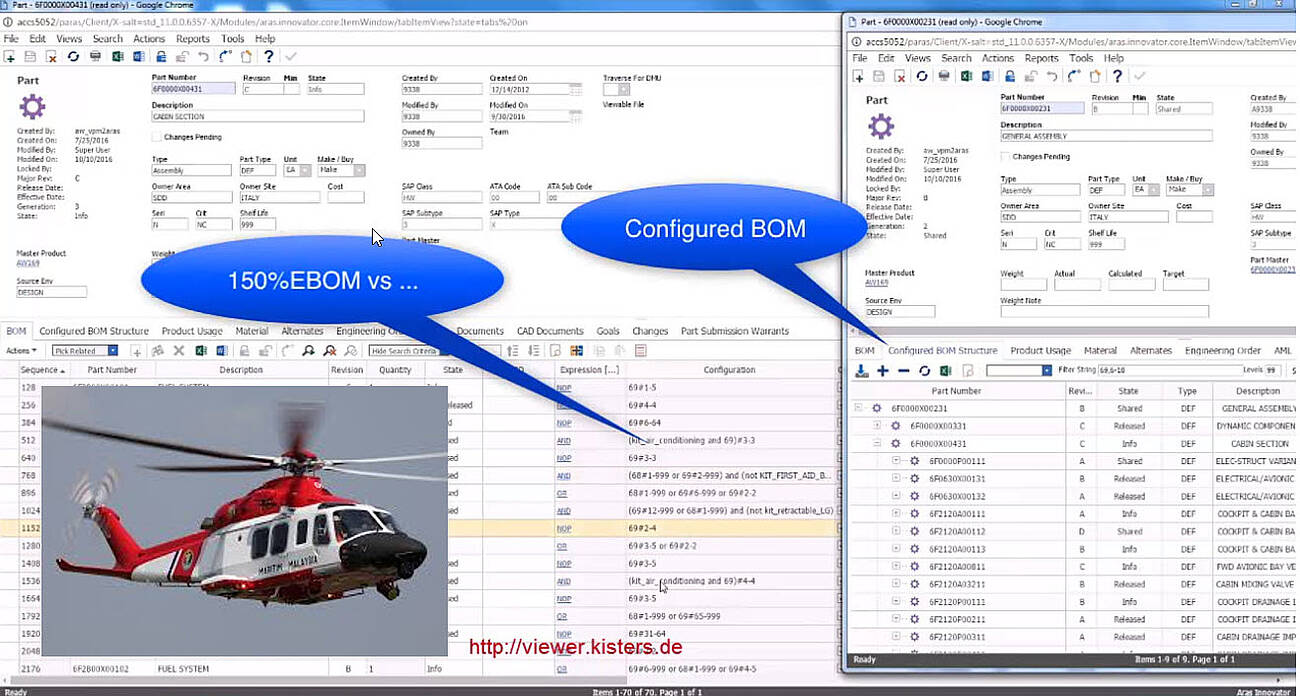

The problem:

Leonardo (Agusta Westland) previously had a product configurator without graphics. The reason was that no technical solution was found that was fast enough on the one hand and on the other could handle the immense amounts of data that were constantly changing during the configuration process. This was very difficult for the sales process.

The solution:

Leonardo has replaced its configurator with a configuration management integrated in Aras PLM with 3D visualization based on Kisters 3DViewStation.

The benefits:

On the one hand, the 100% BOM (bill of materials) for the subsequent processes up to production is already defined in the PLM system. On the other hand, PLM users can now visualize the complete helicopter, which consists of millions of components, in just a few seconds at any time. The 3DViewStation has thus become the most important 3D CAD viewer for Leonardo's Catia data. Customers can now immediately see what their helicopter will look like. This is much more convincing and leads to higher sales.

As a side effect, reviews and analyzes can now be carried out in the context of the entire helicopter or only in areas of subassemblies. A new functionality also supplements the PLM system with the option of selecting a region of the helicopter in the 3D viewer and transferring this spatially selected data to the CAD system Catia for processing.

The problem:

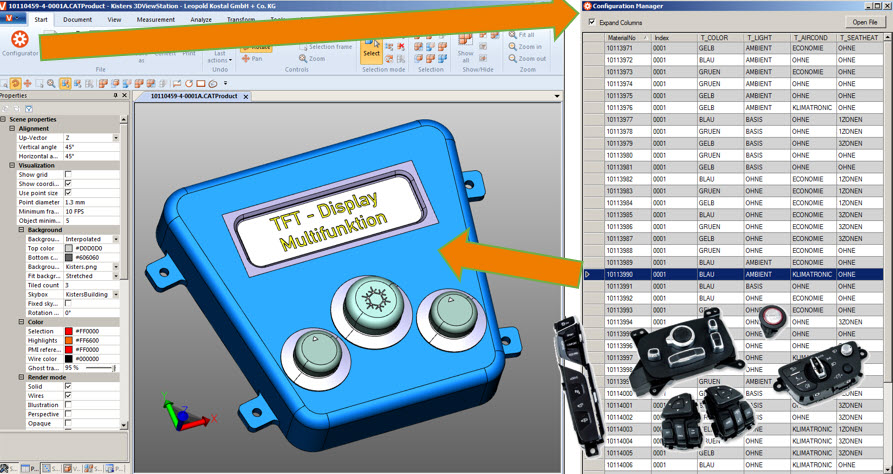

Kostal, manufacturer of electrical components, wanted to offer all users not only the standard configuration when accessing a CAD assembly, but also all configurations in the 3D viewer immediately. This had to be easy to implement and intuitive to use, as this is primarily for non-CAD and non-PLM users.

The solution:

A plug-in was developed for the Kisters 3DViewStation desktop version, which fits seamlessly into the user interface of the 3DViewStation. The plugin, called 3DViewStation Configuration Manager, is fed by an XML file that contains all the possible configurations defined in the PLM system CIM Database. The 3D CAD model from Catia is a so-called 150% model, i.e. a file that contains the superset of all components used, including the correct positions and layers. While switching between the configurations, the plug-in uses API functions to ensure that the components belonging to the selected configuration are displayed in the 3D CAD viewer, while all others are hidden.

The benefits:

Even without a connection to the PLM system, everyone, including non-CAD users, has a quick and easy-to-use solution at hand to visualize and, if necessary, analyze all configurations of an assembly.