Mechanical Engineering

The 3DViewStation stands for smart visualization during product development and during machine operation

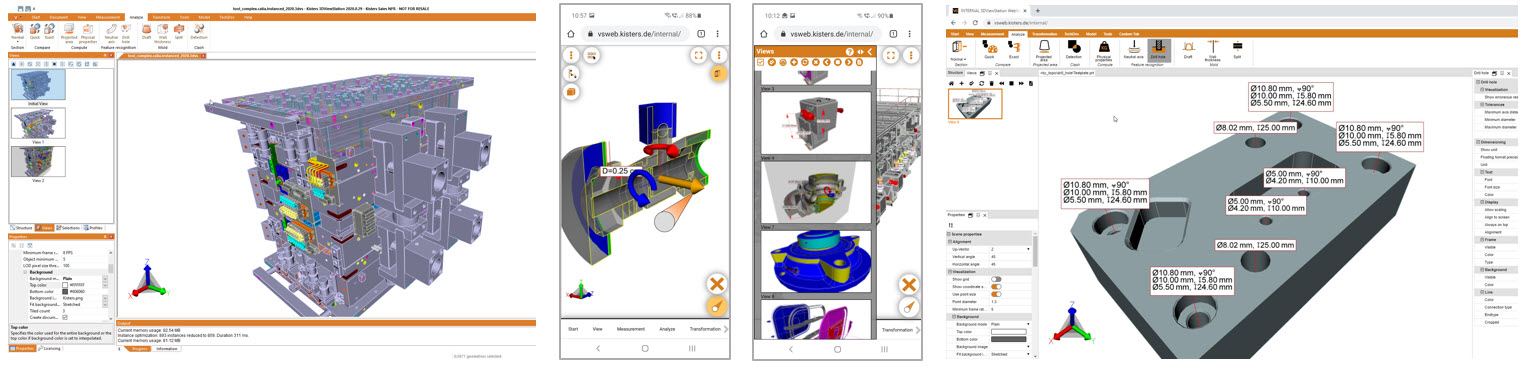

In mechanical engineering, right off the bat we find the need for 3DViewStation’s functions in all engineering-related processes of product development, for example: design reviews, change requests, preparation of quotations, work preparation and the production itself. The reason 3DViewStation is often the tool of choice is due to its modern user interface, high-performance viewing, advanced analysis and integration capability into leading systems. A particular interest for the mechanical engineering industry is the fact that the 3DViewStation product family can convert geometries into a compact, lightweight and extremely fast format. All well-known CAD systems such as Catia, NX, Creo, SolidWorks, SolidEdge, Inventor, and also neutral ones such as JT and STEP are supported. In order to protect your intellectual property, geometries can be changed during the data preparation phase in such a way that you can hardly see it. In turn, this renders the data useless for abuse via reverse engineering (e.g. of illegal spare parts). Alternatively, you can automatically remove all internal parts that are not needed for the discussion at hand.

We would be happy to advise you

Sales Germany

+49 2408 9385 517

Sales USA

+1 916 723 1441

There are other possible applications for the 3DViewStation in mechanical engineering, due to the fact that nowadays many machines, especially the more complex ones, are equipped with an on-board computer. The HMI (Human Machine Interface) has become an important competitive factor. It is no longer just a matter of pressing buttons to operate the machine or outputting error codes from a display, but now you must do this in a spatial context, using the geometries of the actual configuration of the machine. For the HMI itself, Kisters offers both desktop and web-based visualization solutions that can be installed on the respective machine or on a separate system, e.g. for a complete machine park. This allows the user to navigate locally to the objects of his/her interest, request information such as current or historical values and error codes. In the age of IoT, however, we don't just want to see errors on the affected machine, but we also expect the service team to be alerted. If they are using Kisters 3DViewStation WebViewer version on their smartphone while on the road, not only will they get the information about the customer, address, machine and error code, these colleagues will also benefit because they can see exactly where the problem is, with links to documents describing how to fix the problem. This leads to a significantly improved user experience, which we have come to expect in the age of smartphones and apps. If the exact machine configuration - following the idea of the digital twin - is maintained over the lifetime of the machine, both customer and service technician can immediately order the correct spare parts that may be required to solve the problem. Today, machine manufacturers can also benefit from virtual inspections of their machines when using the 3DViewStation VR Edition, as it is capable of processing machines comprised of millions of parts.